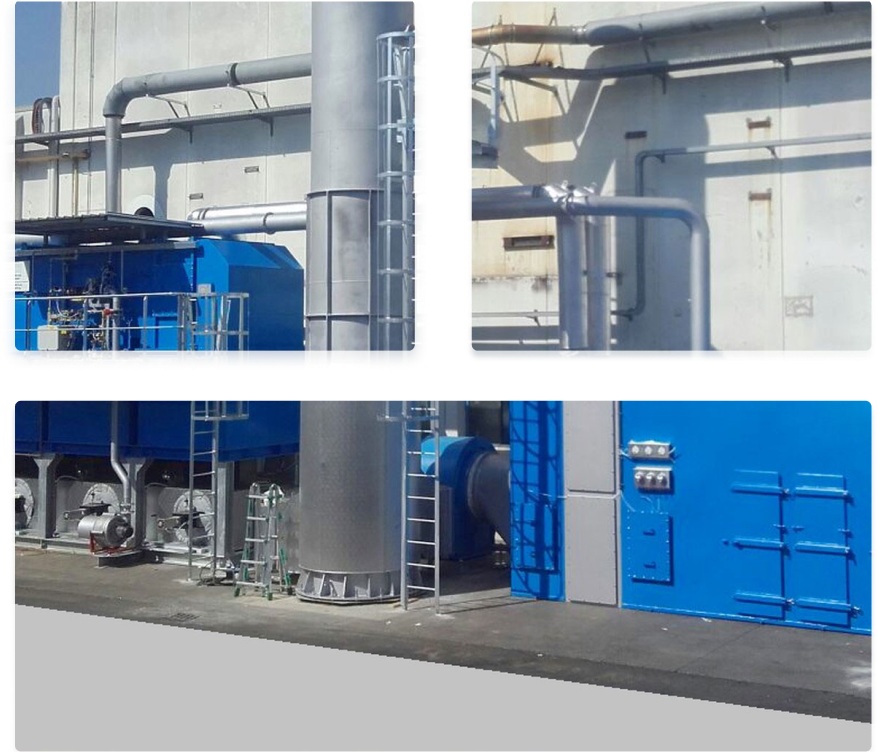

Elimination of volatile organic compounds (VOC’s) through high temperature thermal oxidation.

Possibility of several chambers according to the volume to be treated

Elimination of volatile organic compounds (VOC’s) using high-performance metal-based or precious metal catalysts. One of the applications of this technology is the elimination of NOx from the emissions of internal combustion engines in cogeneration systems, powered by diesel or biofuels such as biodiesel and vegetable oils.

Concentration of high flow streams containing low amounts of volatile organic compounds (VOC’s).

Reduction of 10 to 15 times the flow rate to be treated in the thermal oxidation system, proportionally increasing the concentration of volatile organic compounds (VOC’s)

Control of oil mist emissions and recovery of lube oil and coolant.

Oil treatment in a scrubber and subsequent feed to a distillation column for separation of lube oil and coolant

Removal/adsorption of volatile organic compounds (VOC’s) from process gas streams.

*call to national landline network

© Alquímica 2023, All rights reserved

Powered by BizView

Complaints Book | Privacy Policy